Vacuum Metrology Inc. focuses on the automation of Low Pressure/Vacuum Gauges Calibration and Process Flow. Automation in manufacturing is more important than ever to reduce costs and improve quality. Automation is an imperative in Automobile assembly, and is now recognized as just as valuable to Metrology operations.

There are a number of reasons why Metrology automation is essential:

Production facilities are trying to move Metrology away from the labs to get it embedded directly into the Manufacturing process. In many cases, such as the Lyophilization process, it is necessary to calibrate vacuum gauges in place to account for other components in the system. Automation will have a direct impact on the measurement quality, since people building the product could end up performing the measuring.

Secondly, automation assures reliable and repeatable measurements as well as instant and accurate analyses of complex data. Human error is minimized or completely eliminated in many cases. This is important due to the general lack of and/or expense of hiring qualified engineers or technicians with the required training level.. Traditional metrology laboratories, that receive and calibrate equipment from their customers, benefit from automation by significantly increasing productivity and thus achieving higher profits.

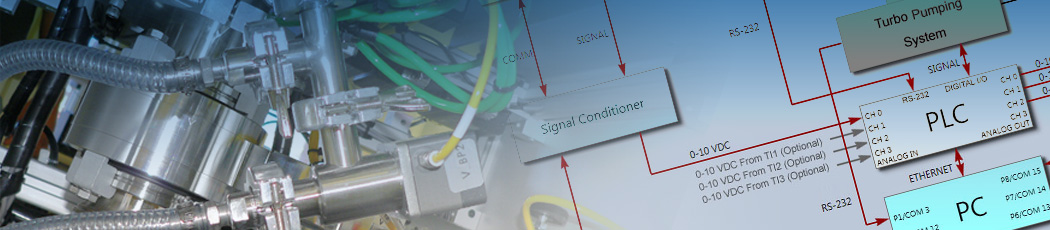

Vacuum Metrology Inc. is passionate about bringing high-level automation to the user. Whether you are an independent Calibration service, Pharmaceutical Manufacturing plant or a Government laboratory, our product is tailored to your specific needs in functionality, range, accuracy, size and cost. Our fully automated stationary and portable calibration systems are available with pressure control range from 1.3x10+5 Pa (1000 Torr) down to 1.3x10-3 Pa (1x10-5 Torr) and with the transfer standards basic accuracy up to .025%

Our Engineering Services group will provide you with the best custom solution based on your specific requirements. An example would be a fully automated calibration system with specific pressure control requirements, throughput, TUR, user interface, data recording and security.

Give us a call. Perhaps we have already solved your problem!