System Description

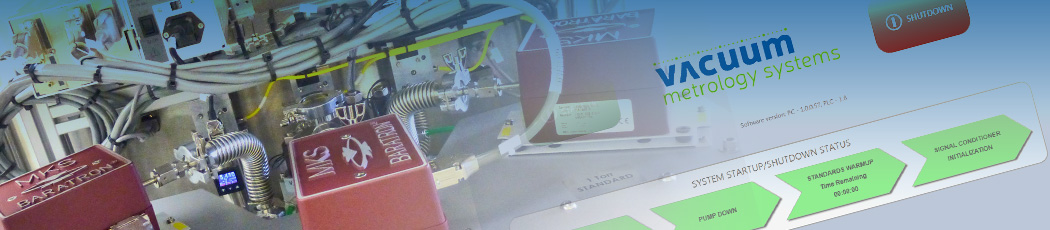

The AVCS3SD Automated Vacuum Calibration System is designed for fast precision automatic, semiautomatic or manual calibration and verification of various vacuum gauges at pressures from 1.3x10-3 to 1.3x10+5 Pa (1x10-5 to 1000 Torr). The system provides calibration capabilities for Capacitance Manometers, Pirani, Piezo, Cold Cathode (Penning), Hot Cathode (Bayard-Alpert) and other types of gauges.

The system is compliant with the requirements of the ISO 3567:2011(E) standard, “Vacuum gauges – Calibration by direct comparison with a reference gauge”

The system incorporates 3 high-accuracy NIST or PTB traceable transfer standards with accuracy of up to ±0.025% (±zero and span), temperature regulated at 45°C; and fully automatic, patent pending, pressure and process control system, along with a Calibration Management Software.

Stainless Steel vacuum chamber incorporates 3 ports for the Transfer Standards and 3 Test Ports equipped with KF16 style flanges. All test and transfer standard ports incorporate automatic failsafe isolation valves. The two stage pumping system consists of a dry (scroll) backing pump and a Turbo molecular pump.

The system is built on a cleanroom compatible aluminum frame with all of the components mounted within the frame footprint. Frame has a built in casters and leveling pads.

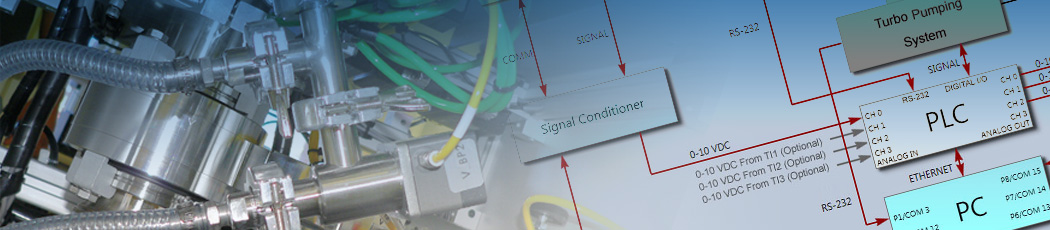

AVCS automation consists of a PC running the GUI and process control and an Allen Bradley PLC responsible for operation of the vacuum hardware and pressure control loop.

AVCS offers a built in Calibration Management Software suite to ensure compliance with ISO 90XX, ISO/IEC 17025, ANSI Z540 and other industry specific quality standards.

Specs

High Accuracy Transfer Standards

up to 3, NIST or PTB traceable, with basic accuracy of up to ±0.025% of the reading

Number of Test Ports

3

Base Pressure

Less than 7x10-5 Pa (5x10-7 Torr)

Pressure Control Range

Fully Automatic Pressure Control from 1.3x10-3 to 1.3x10+5 Pa (1x10-5 to 1x10+3 Torr)

Pressure Control Resolution

Up to 0.01% of set point

Operating Modes

Automatic, Semi-Automatic, Manual, Service

Data Averaging

10 to 99 points

Thermal Transpiration Correction

On/Off for Standards and/or UUTs

(Calculations per Takaishi-Sensui formula)

Process/Calibration Gas

Nitrogen or Dry Air

Dry Pumping System

Scroll + Turbomolecular pumps

Fully Enclosed Cabinet

Eliminates temperature variations and removes the uncertainty contributions caused by the temperature drift.

Cleanroom Compatibility

Fully Compatible

ISO Compliance

Fully compliant with ISO 3567: Vacuum Gauges — Calibration by direct comparison with a reference gauge

Data and System Security

Secure databases for clear audit trail:

- process recipes

- calibration data

- Event logger database

Calibration Management Software Suite

- Create and Print Calibration Certificates

- View and Track calibration history and Trends

- Create and Save unlimited Calibration and UUT recipes

Power Requirements

110/230 VAC, 50/60 Hz, 15A

Dimensions

AVCS Ordering Information

* If you are planning to use your own standards (Please consult our sales department)

Examples:

AVCS3SD-210-Y-AP

3 Standards: 100T, 10T, 1T with Basic Accuracy of ±0.05%

0…10 VDC input for UUTs for Automatic data collection

±15VDC Linear Power Supply for UUTs

AVCS0SD-320-X-M

The System will be pre-configured to use your own 1000T, 100T, 1T standards with Basic

Accuracy of ±0.08%.

Manual data input for all UUT types

Options description:

0…10 VDC Inputs for UUTs (Option “A”):

The System will capture readings from gauges with 0…10 VDC full scale analog outputs. This will cover most of the Capacitance Manometers (a.k.a. Capacitance Diaphragm Gauges). The option may be used along with the optional ±15 VDC linear power supply (see below).

±15 VDC linear power supply (Option “P”):

The power supply will provide the required power to up to 3 Capacitance Manometers without the need for an external controllers/power supplies.

4…20 mA Inputs for UUTs (Option “C”):

The System will capture readings from gauges with 4…20 mA full scale analog output.

RS232/485 Inputs for UUTs (Option “R”):

The System will capture readings from gauges with RS232/485 output. Additional RS232/485 commands, such as Zeroing, can be programmed to be processed automatically as well.

Manual Data Input (Option “M”):

The System will be configured for the manual data input for all UUT types